After designing and publishing our open source , laser-cuttable face shield, various hospitals asked us to supply large quantities as quickly as possible. We are now in full production and the first screens are already in use. Read below how we achieved this last week.

Unprecedentedly fast start-up

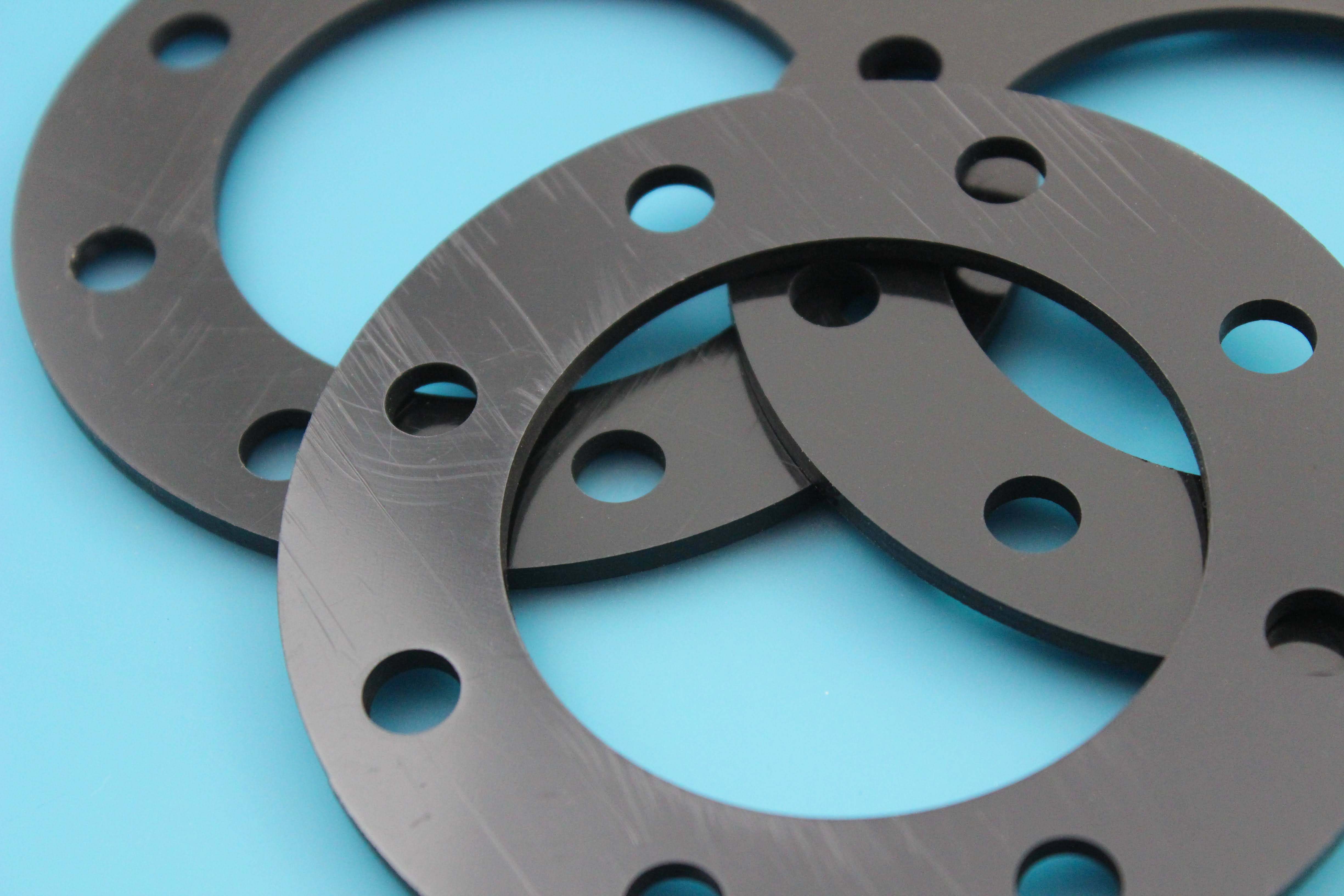

We started production over the weekend. The mask consists of four parts and three different materials. The PET screens can be cut 12 pieces at a time in the SPOTmini machines. This happens quickly; operators are constantly changing materials and therefore do not have time to supply or remove materials. Additional staff was scheduled for this purpose. The polyacetal strips take the longest to make. We chose the autoSPOT machine for this. AutoSPOT is our fastest machine and can load and unload fully automatically. Programming the machine takes a little more time, but after that it runs smoothly. During the first hours of a large production, many things always come to light that could be made more efficient. An extra line in the drawing to make it easier to unload the residual materials, an extra tool to grab parts faster, a better layout of the workshop. Every bit helps.

During this first weekend we have already been able to produce 1000 sets of parts.

Serious numbers

We have scheduled extra working hours on working days. We now work in shifts to get more production hours out of a day. This allowed us to scale up quite quickly to more than 4,000 parts per day on top of our regular production. As a precaution, we decided to temporarily not offer the urgent delivery option ofsnijlab.nl.

Material supply became dire at this point. European production chains are currently disrupted and many suppliers cannot supply (enough). With very welcome help from some customers and partners, we were eventually able to source enough materials. The result was that we had to temporarily switch to thicker polyacetal. To keep the stiffness of the mask the same and to make the connection work, we created an alternative design on the fly. This way we could compensate for the thickness difference and still continue to make sufficient and well-functioning masks.

Volunteers

In the first two days, more than 100 volunteers volunteered to help with assembly. An assembly line was set up in a short time in the play factory that was closed due to the corona measures. Now a team of 12 volunteers, led by Gerard, works every day to assemble and pack the screens. The finished screens are delivered to the ErasmusMC every day.

Within a week of ordering, more than 5,000 face shields were in the hospital and in use. More than 20,000 screens have now been purchased.

Digital production within the Netherlands

This project shows how valuable it is to be able to produce locally. It also shows the power of digital production; Because we are free in form and material, we can start immediately and deal flexibly with challenging circumstances such as material shortages.

We have solved the main drawback of digital production, the low capacity, by developing innovative machines that can laser cut quickly and serially.

Serial digital production fills the gap between 3D printing and mass production.

We are happy and proud that we can contribute to this crisis.

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.