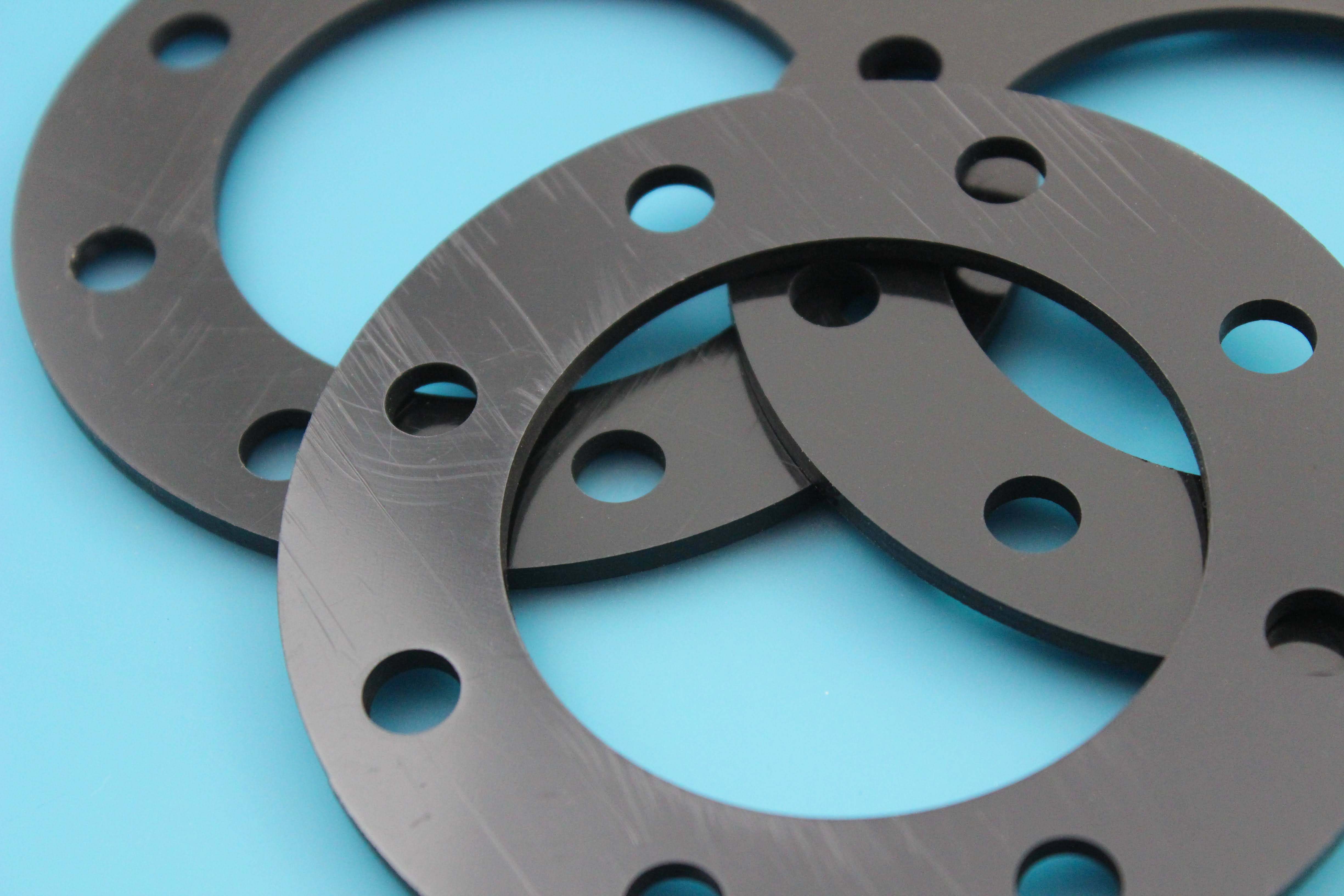

We are designers, makers, engineers, entrepreneurs and laser enthusiasts. Since 2012, we've been helping people like you produce their own designs.

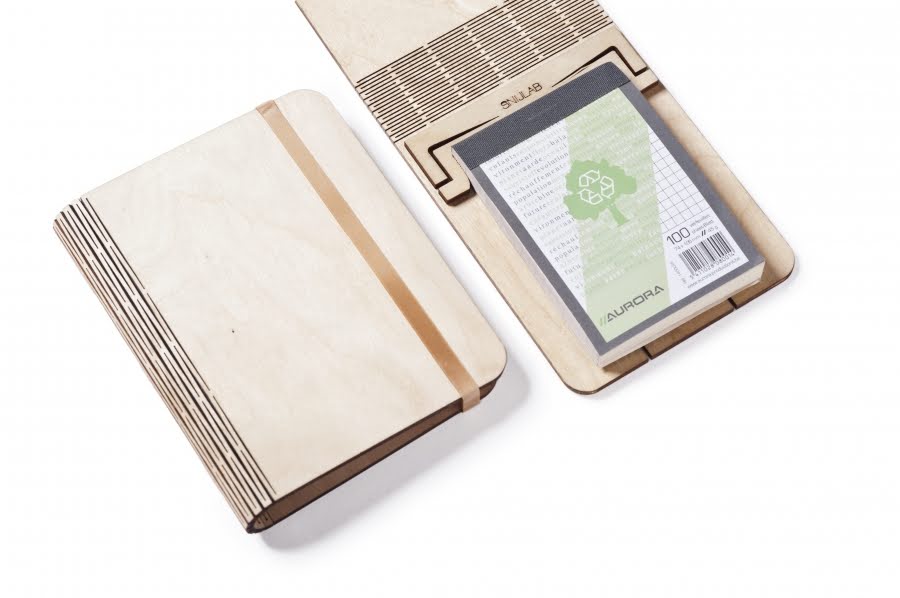

Snijlab makes laser cutting in wood and plastic easy and accessible. Through a convenient online ordering environment, helpful support, the best materials, and prompt delivery.

This allows you to produce easily and cost-effectively. Whether you create unique projects, want to produce custom parts, market your own product or just want to experiment, we make it easy.

We do this so that you can make it with your product.

Founders of Snijlab

In 2009, Christian Waber and Jiskar Schmitz founded Snijlab, since then they have been committed to making laser cutting accessible to everyone.

Meet the team

Sven van der Velden

Operator and warehouse manager

Guy Remi

Operator

Maaike Hool

Sales engineer

Justin Nelissen

Production assistant

Paula Stoffijn

Marketer

Thomas Boerendonk

Planner

Christian Waber

Founder

Iskar

Founder

Vacancies

Snijlab currently has no vacancies.

Open applications are welcome at christian@snijlab.nl for the attention of Christian Waber.