Loyal Snijlab customer Joris Kuipers will be exhibiting at OBJECT 2023 , and for the occasion we asked him a number of questions.

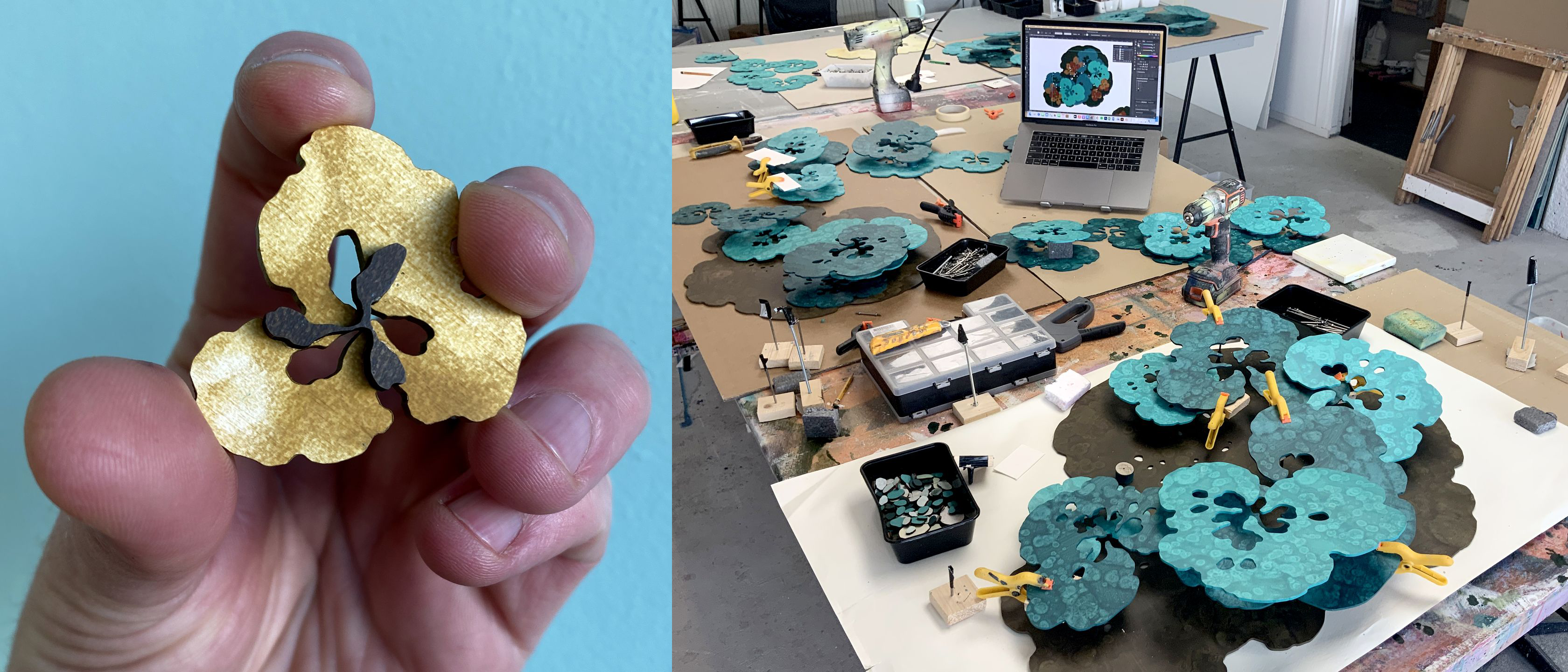

Left: BERM wearable, Joris Kuipers. Right: in the studio with Joris Kuipers

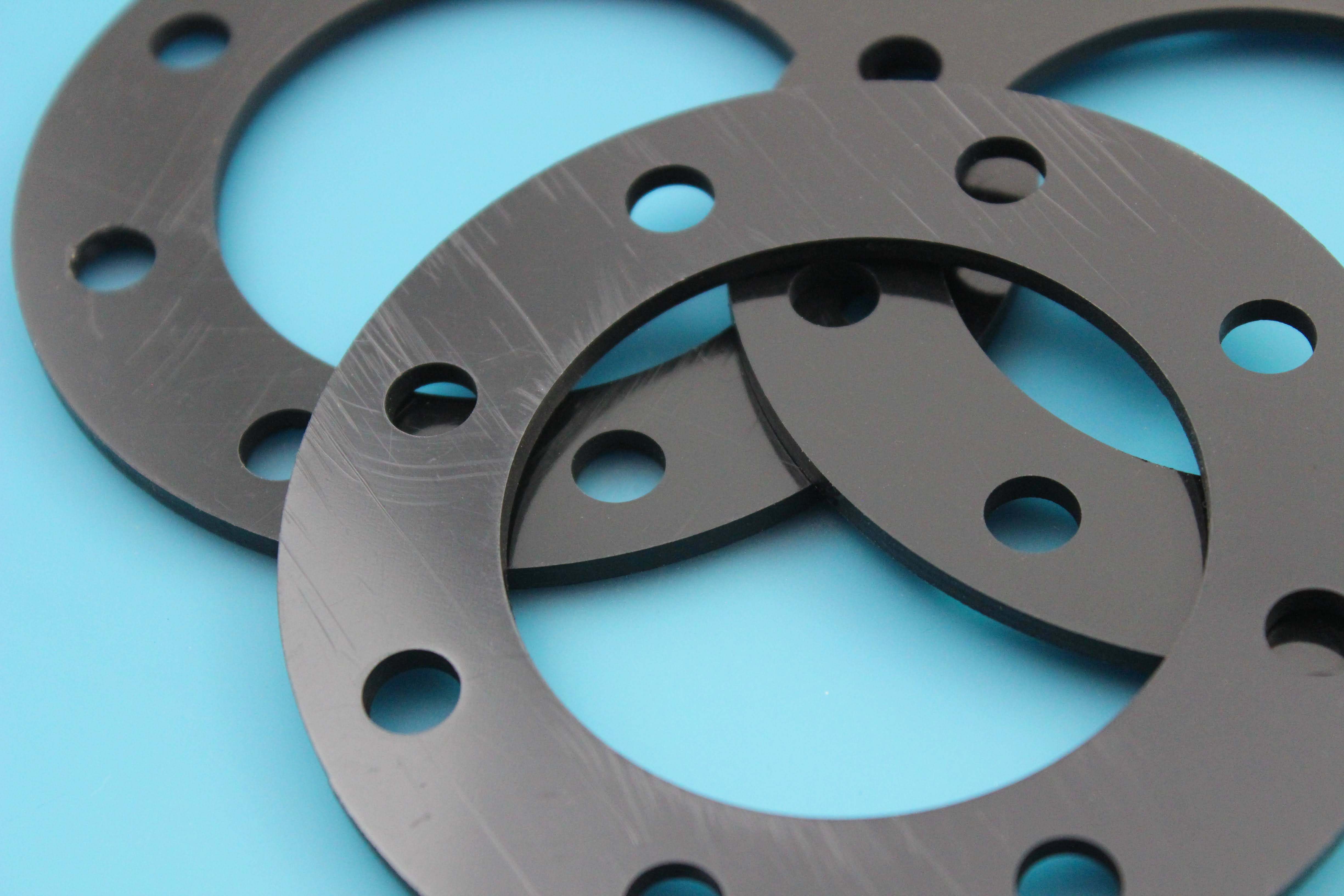

“Snijlab has been taking care of my cutting work for 6 years now because the cutting quality is very good: the machines cut in such a way that there is little soot on the sides and little deposits on the top.” - Joris Kuipers

Joris Kuipers is a visual artist, his sculptural oeuvre largely consists of explosive flower-like shapes. He puts together impressive spatial creations with flat abstract shapes. Kuipers has these shapes cut out at Snijlab.

In 2016, Kuipers had parts laser cut at Snijlab for his wall sculpture Multiple for the first time. For this purpose, he cut out his parts independently at the Fablab of a university of applied sciences. But this laser cutter was no longer large enough and, moreover, the cutting edges cut at the Fablab gave off a lot of soot.

Laser cutting is the burning or pulverization of material with a focused beam of light, in a controlled and very precise manner. As a result, when laser cutting wood, soot will always form on the cut edges to some extent. But with the right settings and a good machine, soot on cut edges can be minimized. For a large production run with many irregular shapes, minimizing soot deposits can quickly save many hours of post-processing.

Joris, we have been cutting out the shapes for your works of art for years. But can you tell us how you create these impressive shapes?

Kuipers: I start with a digital sketch that I make on an iPad, which I then convert into a styrofoam model. Recently I also started making scale models in Blender, because I can easily import my Illustrator drawings into it. This is how I make my design.

I always first draw the shapes that are going to be cut out analogue at full size before I digitize them. This preserves the whimsicality of my handwriting.

At Snijlab I supply painted and varnished panels. You will then provide these plates with a protective film so that no soot deposits form on the top and bottom of the plates during laser cutting. I always pick up and deliver my orders by bike, my studio is around the corner.

As soon as I receive the laser-cut shapes, I finish the edges, leaving the protective film in place. Once the edges are finished in the correct color, I remove the protective film and assemble the parts together with threaded rods that I have specially developed for this.

How interesting to hear how you work. Do you also use other techniques besides laser cutting?

Kuipers: You can regard my wall sculptures as spatial paintings. I use a self-developed painting technique, which you could compare with Faux Peinture, without literally depicting a material (such as marble).

For this I use birch plywood panels, which I provide with a few layers of transparent acrylic paint. To get a spotty texture in the paint layer, I then process them with different mediums, this gives more depth to the shapes.

Can you give an example of a small and a large work that you have made?

Kuipers: The smallest work is currently 5 cm: a wearable based on the shapes from the wall sculpture BERM, which will be presented at OBJECT Rotterdam 2023 .

In 2019, I made a wall relief of a total of 12 meters for Royal Caribbean Cruises for one of their ships. There is also a nice report on the Snijlab site .

Nocturnal Garden I & II, Joris Kuipers

To achieve the best results for Joris, we regularly carry out cutting tests with different types of paint and finishes, such as plates treated with acrylic paint and high-gloss varnish, or wood covered with gold leaf. For each of these finishes we looked for the best setting to minimize soot and deposits.

What do you think of the collaboration with Snijlab?

Kuipers: The Snijlab team is solution-oriented and thinks about different production methods. I have always experienced the team as very customer-friendly, both at the counter and by email, your questions are answered quickly and professionally.

The Snijlab website is clear, and ordering is easy because you don't have to wait for someone to prepare a quote for you. You can calculate and order prices independently online, so you can immediately see what the costs of a production will be. There is an option to have your work produced quickly or you can wait a little longer, which is more economical. This allows you to consider what is important for your project at that moment.

In addition, Snijlab is within cycling distance of my workshop. This makes dropping off and picking up my materials very easy, I never have to wait for a postman.

What are you going to work on in the coming year?

Kuipers: I am currently putting the finishing touches to BERM, a modular wall sculpture. This will be on display during OBJECT Rotterdam , curated by Anne van der Zwaag. It will then be further expanded for a presentation during the Salone de Mobile in Milan. The work is shown by Masterly, the Dutch in Milano, curated by Nicole Uniquole.

After these fairs I will work on a series of 3 multiples. A small, medium and larger sculpture, which together create a wall-filling sculpture.

Thank you Joris, we look forward to admiring your work on Object.

Read more about laser cutting wood here.

Do you have a project with a more challenging material in mind? Read more about the options here or contact info@snijlab.nl or +31 10 3070 949. We will always have to test self-supplied material first before we can accept an order.

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.