How Snijlab helps build the stringed instrument 'Nerdy Gurdy' and keeps its production flexible and affordable with laser cutting

How the Nerdy Gurdy came about

A handmade one hurdy-gurdy is expensive

The wooden, handmade instruments are very valuable. Brand wants to bring an affordable version to the market using digital techniques. Also made of wood and with a similar sound quality to a traditional one hurdy-gurdy .

SolutionOur own design for a laser-cut instrument

In daily life, Brand works as a mechanical engineer and is therefore experienced in making industrial designs. A completely different sport, but he does have the necessary skills. With advice from instrument makers and musicians, he designs a kit that is easy for consumers to assemble.

Prototyping costs must be kept within limits

Brand is at the beginning of a challenging quest. The hurdy-gurdy must sound good, the construction kit must remain simple and there is a lot of consultation with external parties to fine-tune the design. This can be a costly process, with many prototypes and adjustments.

SolutionWorking cost-efficiently with digital technology

Brand chooses digital production techniques, which save him time and money. Laser cutting and 3D printing give him the freedom to experiment and tinker without limits. After each improvement there is a quick adjustment to the digital drawing, and then a new laser-cut prototype. For example, if he saw the prototypes himself, it would take so much more time and the result would be less detailed.

Start with small-scale production

After four years, Brand finally has a good prototype, called the 'Nerdy Gurdy'. As far as production is concerned, he wants to start quietly. After all, there is no guarantee that the instrument will be an immediate success. Starting with a small print run is safe, but with many common production techniques this is very disadvantageous.

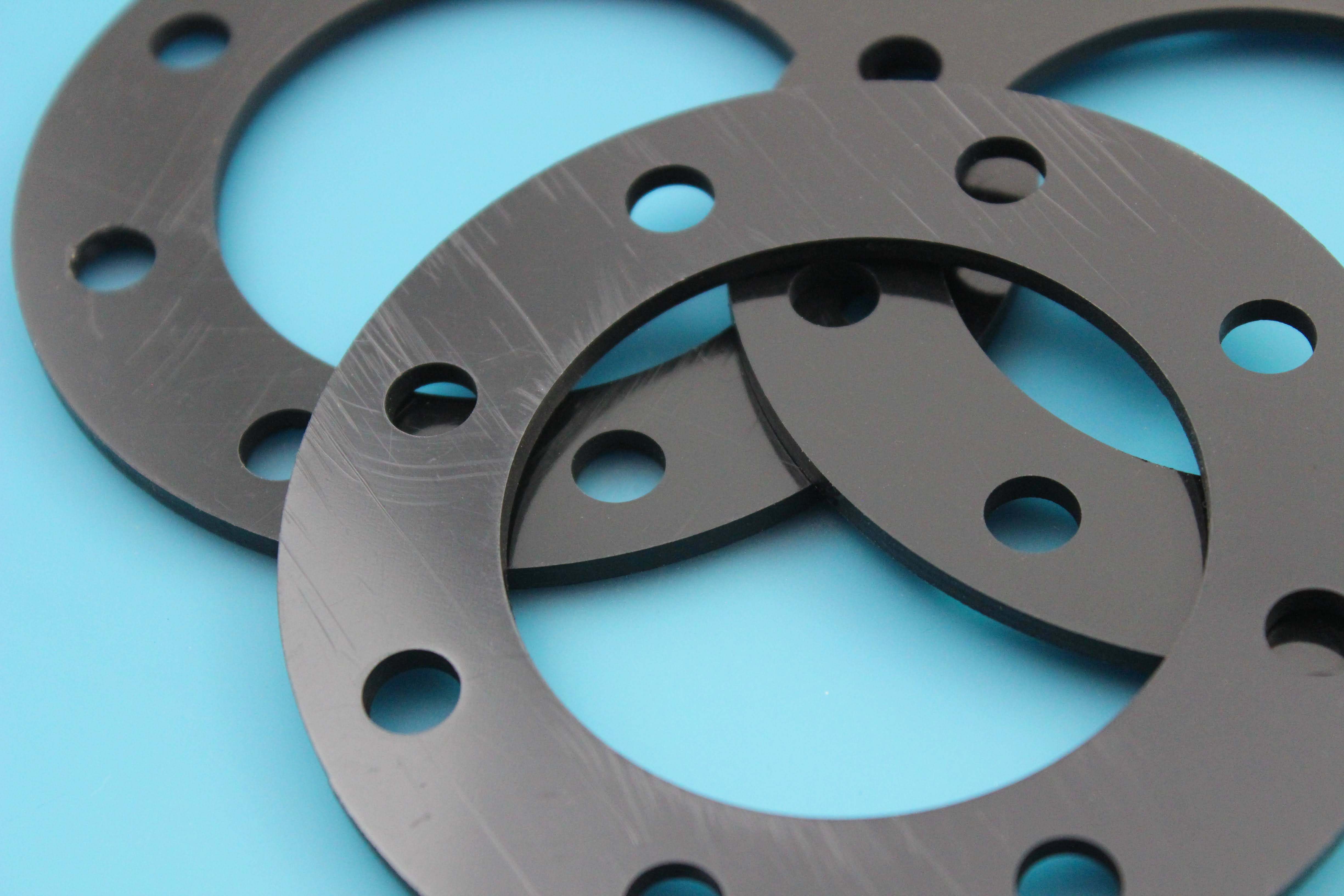

SolutionLaser cutting keeps the price favorable regardless of the order size

Brand orders twenty construction kits at a time. In this way, the investment risk remains as low as possible. Depending on its success, Brand can place increasingly larger orders.

Growing sales requires optimization

The Nerdy Gurdy is selling better and better, which is positive in itself. The production of the instrument is still small-scale, but due to increasing demand it is becoming more serial work. It is therefore obvious to switch to a laser cutter with a larger capacity, but the design is not yet suitable for this.

SolutionAdjusting design for automated laser cutter

Snijlab advises Brand to rearrange his drawings so that they fit into AutoSPOT. This is an automated laser cutter, suitable for serial work. This switch has more advantages: the cost price is lower and the quality of the end product is better. The Autospot does not leave smoke deposits on the wood, which is the case with traditional machines. This means that the deposit does not have to be sanded off manually, which saves time.

Construction kit must be user-friendly for consumers

In the transition to the Autospot, a new issue is immediately addressed. How can the design be made even more user-friendly? A consumer can order the instrument ready-made, but also as a kit. Assembly should be simple.

Add 'tabs' for easy construction

'Tabs' are added to the design. Tabs are small interruptions in the cutting line. Visually, this gives the typical character of a construction kit, but it also increases ease of use. Carefully placed tabs keep the parts in place in the plate and can be easily pushed out.

More about the Nerdy Gurdy

The Nerdy Gurdy design is open source and licensed as CC BY-NC 4.0 . The working drawings are available on the online makers community Thingiverse .

The stringed instrument continues to evolve. Since the first model, several new versions have been released. You can order the Nerdy Gurdy ready-made or as a kit: www.nerdygurdy.nl .

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.